+86-755-28062190

SetHome

AddFavorite

Welcome to Sanye Technology Co., LTD. official website!

+86-755-28062190

SetHome

AddFavorite

Welcome to Sanye Technology Co., LTD. official website!

PRODUCTS

CONTACT US

- Address

- 3rd Floor, Building 8-2, Kukeng Tongfu Industrial Zone, Guanlan Street, Longhua District, Shenzhen City, Guangdong Province

- Phone

- +86-755-28062190 / 13728860027

- wangym@sayestech.com

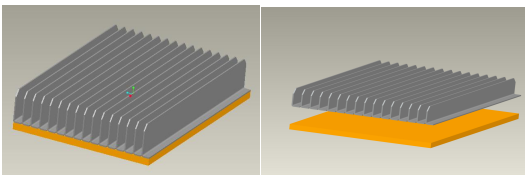

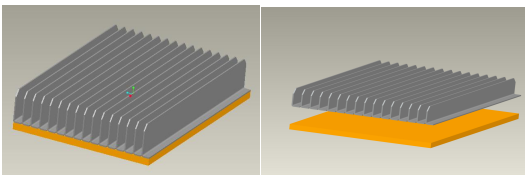

As The Power Of Electronic Products Continues To Increase And The Size Of The Products Decreases, The Wide Application Of High-Density Welded Heat Sinks Has Been Spawned. Welded Radiators Are Generally Welded By A Base Plate And Fins. The Base Plate And Fin Materials Can Be Flexibly Combined With Copper Or Aluminum. The Use Of Soldering Technology Can Keep The Physical Properties Of The Material Unchanged And Meet Higher Precision Requirements.

High Fin Density - Greatly Increasing The Heat Dissipation Area;

Light Weight And Small Size - Adapting To The Requirements Of Small Or Lightweight Products;

Mixed Welding Of Copper And Aluminum - Taking Into Account The Better Heat Transfer Of Copper And The Weight Of Aluminum The Advantage Of Being Lighter

Is Welding In Specific Areas - You Can Weld The Cooling Fins Or Heat Transfer Components Only In The Areas Where Heat Dissipation Is Needed.

Low Mold Costs - Save The Expensive Mold Costs Of Large Aluminum Profiles

. The Bottom Plate Can Be Precision Processed - The Bottom Plate Can Be Processed With Precision Cavities Or Complex Avoidance

Fin Type:

High Fin Density - Greatly Increasing The Heat Dissipation Area;

Light Weight And Small Size - Adapting To The Requirements Of Small Or Lightweight Products;

Mixed Welding Of Copper And Aluminum - Taking Into Account The Better Heat Transfer Of Copper And The Weight Of Aluminum The Advantage Of Being Lighter

Is Welding In Specific Areas - You Can Weld The Cooling Fins Or Heat Transfer Components Only In The Areas Where Heat Dissipation Is Needed.

Low Mold Costs - Save The Expensive Mold Costs Of Large Aluminum Profiles

. The Bottom Plate Can Be Precision Processed - The Bottom Plate Can Be Processed With Precision Cavities Or Complex Avoidance

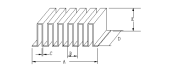

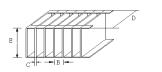

Fin Type:

Organ Piece

Single Fold Piece

-

Phone

+86-755-28062190 -

Wechat

CN

CN