+86-755-28062190

SetHome

AddFavorite

Welcome to Sanye Technology Co., LTD. official website!

+86-755-28062190

SetHome

AddFavorite

Welcome to Sanye Technology Co., LTD. official website!

CONTACT US

- Address

- 3rd Floor, Building 8-2, Kukeng Tongfu Industrial Zone, Guanlan Street, Longhua District, Shenzhen City, Guangdong Province

- Phone

- +86-755-28062190 / 13728860027

- wangym@sayestech.com

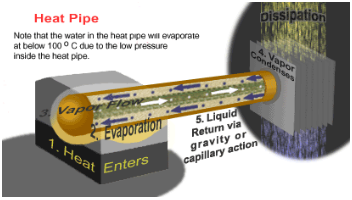

Typical Structure And Working Principle Of Heat Pipe

The Heat Pipe Is Composed Of A Tube Shell, A Liquid-Absorbing Wick And A Working Medium. The Working Section Of The Heat Pipe Can Be Divided Into Three Parts: Evaporation Section, Adiabatic Section And Condensation Section.

When The Evaporation End Collects Heat, The Working Medium Soaked In The Fine Liquid Core Is Evaporated Through The Tube Wall. The Steam Flows To The Condensation End Under The Pressure Difference Formed Between The Evaporation And Condensation Ends. Since The Condensation End Is Cooled, The Steam Condenses. As A Liquid, It Releases Its Vaporization Potential. The Condensed Gas Transports The Condensate Back To The Evaporation Section By The Capillary Force Generated By The Combination Of The Liquid Absorbing Core And The Liquid To Form A Working Cycle.

Characteristics Of Heat Pipes

1. The Heat Transfer Capacity Of The Heat Pipe Is High

Because The Heat Transfer Of The Heat Pipe Mainly Relies On Absorption During The Phase Change Of The Working Fluid. Releases The Latent Heat Of Vaporization And Heat Transfer Of Steam Flow, So Its Heat Transfer Capacity Is Dozens Of Times Higher Than Other Thermal Conductive Materials.

2. The Heat Pipe Has Good Uniform Temperature Characteristics.

When The Heat Pipe Is Working, The Steam In The Pipe Is In A Saturated State, And The Temperature Difference During Steam Flow And Phase Change Is Small. Therefore, The Temperature Gradient Along The Evaporation End Surface Of The Heat Pipe Is Very Small, And A Uniform Heat Flow Temperature Can Be Automatically Formed.

3. The Ability To Have Variable Heat Flow Density.

Since The Evaporation And Condensation Spaces In The Heat Pipe Are Separated, If A High Heat Flow Density Is Input At The Evaporation End, A Low Output Heat Flow Density Can Be Obtained At The Condensation End, Realizing The Role Of A "Thermal Transformer".

4. It Has Good Constant Temperature Characteristics

And Uses A Controllable Heat Pipe Filled With Inert Gas. When The Heat At The Input End Changes, The Condensation Area At The Condensation End Changes Due To Changes In Steam Pressure To Maintain A Constant Temperature Of The Heat Source.

Common Heat Pipe Specifications

|

Heat Pipe Specifications Are As Follows: |

||||||||||||||||||||||||||||||||||||

|

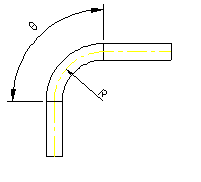

Heat Pipe Bending Restrictions

|

|

|

|||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||

-

Phone

+86-755-28062190 -

Wechat

CN

CN