+86-755-28062190

SetHome

AddFavorite

Welcome to 三烨科技有限公司 official website!

+86-755-28062190

SetHome

AddFavorite

Welcome to 三烨科技有限公司 official website!

CONTACT US

- Address

- 广东省深圳市龙华区观澜街道库坑同富裕工业区8-2栋三楼

- Phone

- +86-755-28062190 / 13728860027

- wangym@sayestech.com

With The Continuous Development Of Electronic Technology, The Heating Power Consumption Of High-Power Devices Is Increasing, And The Heat Flow Density Is Increasing. Product Thermal Design Has A Crucial Impact On Product Reliability. To Carry Out A Good Heat Dissipation Design For High-Power Devices, You Must First Understand The Thermal Performance Indicators Of The Power Devices, Then Select The Appropriate Heat Dissipation Method, Correct Air Duct Design And Perform Necessary Optimization Analysis Of The Radiator, And Finally Standardize And Correct Installation. The Heat Sink Enables The Device To Achieve Optimal Heat Dissipation.

1. Thermal Performance Parameters Of The Device

Most Device Manufacturers Will Provide Information Such As The Device's Soldering Temperature, Packaging Form, Operating Temperature Range, Device Junction Temperature Limit, Internal Thermal Resistance, Etc. These Parameters Are The Basis And Prerequisite For Thermal Design. Some Common Thermal Parameters Are Explained One By One Below:

TDP—Thermal Dissipation Power Of The Device, Unit W (Watt), Indicating The Actual Amount Of Heat Generated By The Device

Tc - Device Case Temperature, Unit ℃

Tj - Junction Temperature, Unit ℃. As Junction Temperature Increases, Semiconductor Device Performance Will Degrade. If The Junction Temperature Exceeds The Maximum Limit, The Device Life Will Be Extremely Reduced Or Even Burned. This Is The Focus Of Thermal Design.

Ta - Ambient Temperature, Unit ℃

Rja - Thermal Resistance From Junction To Environment, Unit ℃/W

Rjc - Thermal Resistance From Junction To Device Case, Unit ℃/W

In The Final Analysis, The Main Task Of Thermal Design Is To Satisfy: Tj<Tj(Max) And Leave An Appropriate Margin (Usually More Than 10% Margin Should Be Ensured).

Tj(Max)=P* Rjc+ Tc(Max)

Tc(Max) Is The Maximum Temperature On The Device Surface. Obviously, The More Successful The Heat Dissipation Design Is, The Lower The Tc(Max) Will Be.

2. Selection Of Heat Dissipation Methods

The Choice Of System Heat Dissipation Method Should Fully Consider The System's Heating Power Consumption, Temperature/Volume/Weight Requirements, Protection Level, Operability Of The Heat Dissipation Device, Price And Many Other Factors, And Finally Choose The Most Effective And Effective Heat Dissipation Method For Your Product.

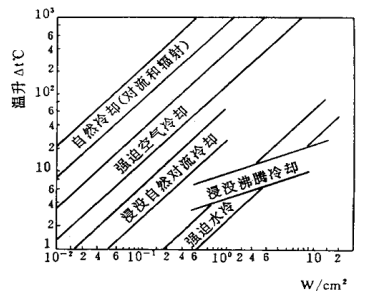

Heat Dissipation Is Mainly Divided Into: Natural Heat Dissipation And Forced Air Cooling. Liquid Cooling Etc. The Commonly Used Heat Dissipation Method Is Still Air Cooling. The Following Table Reflects The Relationship Between Heat Flow Density And Temperature Rise Under Different Heat Dissipation Methods.

Natural Heat Dissipation: Heat Is Brought To The Surrounding Space Through Natural Convection Of Air. This Heat Dissipation Method Can Be Used In Situations Where The Heating Power Is Not Large And The Weight, Temperature And Other Requirements Are Not High. Advantages: Simple Structure, No Noise, Low Price.

Forced Air Cooling: For Devices With Large Heating And Power Consumption, It Is Necessary To Use Forced Air Cooling, Especially When Combined With Some High-Efficiency Radiators To Achieve Ideal Heat Dissipation Effects. Because The Heat Transfer Efficiency Of Forced Air Cooling Is High, It Is Generally Several Times That Of Natural Heat Dissipation. Advantages: High Heat Dissipation Efficiency, Product Weight Can Be Greatly Reduced.

3. Fan Selection And Air Duct Design

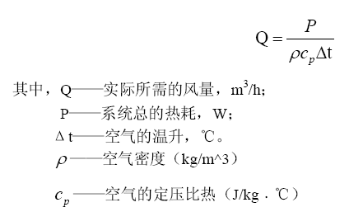

If The System Uses Forced Air Cooling, Choosing An Appropriate Cooling Fan Directly Determines The System's Cooling Conditions. To Select A Fan, You First Need To Determine The Cooling Air Volume Required By The System, Which Is Calculated Using The Following Formula:

Among Them, ΔT Represents The Temperature Difference Between The Inlet And Outlet Of The System.

The Fan Selection Should Be Comprehensively Evaluated And Confirmed Based On System Air Volume Demand, System Resistance, Fan Characteristic Curve And Other Requirements.

The Actual Air Duct Of The Forced Air Cooling System Is Very Critical. The Air Duct Is Generally Divided Into Two Methods: Supply Air And Exhaust Air. The Advantages And Disadvantages Of These Two Methods Are:

Air Supply Method:

A. The Air Flow Near The Fan Outlet Is Mainly Turbulent Flow, And The Local Heat Exchange Is Strong. It Is Suitable For Situations Where Heating Components Are Concentrated. In This Case, The Main Air Outlet Of The Fan Must Be Aligned With The Concentrated Heating Components.

B. When Blowing, A Positive Pressure Will Be Formed In The Equipment, Which Can Prevent Dust In The Gaps From Entering The Equipment.

C. The Fan Will Not Be Affected By The Heat Dissipation Of The System. It Works At A Lower Air Temperature And Has A Longer Fan Life.

Exhaust Method:

A. Uniform Air Supply, Suitable For Situations Where The Heating Devices Are Evenly Distributed And The Air Ducts Are Complex.

B. The Flow Entering The Fan Is Mainly Laminar Flow.

C. The Fan Will Work Under High-Temperature Airflow From The Air Outlet, And Its Lifespan Will Be Affected.

D. Negative Pressure Is Formed In The System, And Dust In The Gaps Will Enter The Cabinet/Box

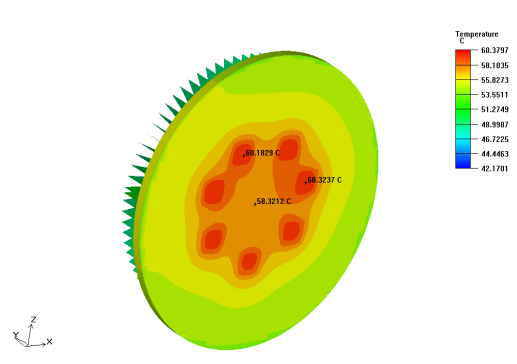

4. Radiator Optimization

The Optimization Of High-Power Device Radiators Mainly Involves Optimizing The Design Of Parameters Such As Radiator Substrate Thickness, Tooth Plate Thickness, Spacing, Height, And Surface Treatment Methods. With The Continuous Advancement Of Computer Simulation Technology, We Can Rely On Electronic Thermal Simulation Analysis Software To Optimize The Radiator, And The Optimization Results Are Accurate And Intuitive.

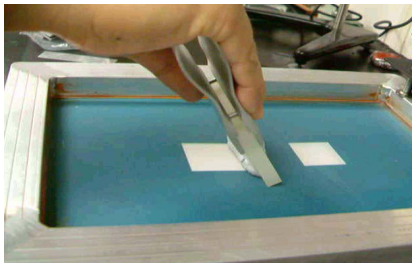

5. Correct Installation

Correct And Reasonable Installation Can Ensure That Cooling Products Can Perform Their Functions Well And Improve The Overall Reliability Of The Product. We Know That During The Installation Process Of Heat Dissipation Products, It Is Mainly Necessary To Ensure That The Device And The Radiator Have Good And Sufficient Thermal Contact - To Make The Contact Thermal Resistance Between The Device And The Radiator As Low As Possible.

The Main Factors That Affect Contact Thermal Resistance Are As Follows:

1. Contact Surface Flatness

2. Contact Pressure Between Heat Dissipation Products And Heat Sources

3. Selection And Application Of Thermal Interface Materials

It Is Recommended To Use A Special Jig To Correctly Apply The Interface Material. You Can Refer To The Picture Below To Ensure That The Thermal Interface Material Is Uniform. Usually The Thickness Needs To Be Controlled Between 0.12-0.18mm.

-

Phone

+86-755-28062190 -

Wechat

CN

CN